Media Release: CKW & FLOWDAYS WIN SUPPLY MANAGEMENT AWARD 2018 EUROPE

CKW and flowdays won the most important European award in the procurement industry with the Supply Management Award. The award honors the innovative and agile procurement process for a new intranet from CKW in weeks instead of months.

CKW and flowdays won the most important European award in the procurement industry with the Supply Management Award. The award honors the innovative and agile procurement process for a new intranet from CKW.

In a so-called Pocathon (Proof of Concept and "Thon" by Marathon), the teams and products of three intranet providers were put through their paces for two days. The goal was to implement real CKW application needs.

"On the one hand, we wanted to test whether the products actually meet our expectations, whether the intranet fits in with CKW's IT landscape and whether a legal, commercial partnership agreement could be found," says Andreas Schneider, Head of Supply Chain Management at CKW. "With the approach 'Lean-agile-Procurement', we were able to significantly shorten the time from the idea to the productive start of the new intranet compared to traditional approaches». Specifically, CKW signed a letter of intent with the winner after exactly two days, 1st Quad. Usually, such a procurement process takes weeks. Just six months after the Pocathon, CKW's new intranet was put into operation in mid-October 2018. A further advantage for the project managers of CKW was that they did not get to know the salespeople of the three suppliers, but specifically the implementation team.

Recently, Andreas Schneider, Head of Supply Chain Management of CKW, Yvonne Ruckli, Project Manager of CKW and Mirko Kleiner, Agile Coach of flowdays in Prague, accepted the award.

Caption: Recently, Andreas Schneider, Head of Supply Chain Management of CKW (2nd from left), Yvonne Ruckli, Project Manager of CKW (3rd from left) and Mirko Kleiner, Agile Coach of flowdays (4th from left) in Prague were honored answer.

DOWNLOADS

Downloads via CKW Website

CONTACT

Business Agility Institute - Agile Contracting & Procurement Symposium

6 great speakers from 3 continents; Dean Leffingwell , Mirko Kleiner, Stewart James, Manjit Singh, Larry Cooper and Allan Kelly shared their experiences, tips and even their templates with you at the Agile Contracting & Procurement Symposium organized by the Business Agility Institute. Find my slides for FREE DOWNLOAD here.

6 great speakers from 3 continents; Dean Leffingwell , Mirko Kleiner, Stewart James, Manjit Singh, Larry Cooper and Allan Kelly shared their experiences, tips and even their templates with you at the Agile Contracting & Procurement Symposium organized by the Business Agility Institute. Find my slides for FREE DOWNLOAD here.

First of all a big thank you to the business agility institute, the organizer of this online symposium!

Recorded online Symposium

Find below the recorded online symposium for re-viewing.

Speakers & Slides

1. Dean Leffingwell

SCALED AGILE, INCSAFE CREATOR AND CHIEF METHODOLOGIST

"Agile Procurement & Contracts "

2. Mirko Kleiner

FLOWDAYSCREATOR LEAN-AGILE PROCUREMENT

"Procurement on Disruption" - Find the Slides & Case Study for FREE DOWNLOAD below.

3. Stewart James

AGILLEXMANAGING DIRECTOR | SOLICITOR

"Why lawyers don’t like Agile"

4. Allan Kelly

ALLAN KELLY ASSOCIATESPRINCIPAL

"Agile Contracts: A Template"

5. Larry Cooper

ADAPTIVEORG COFOUNDER

"It's never just "an IT Project"

6. Manjit Singh

AGILIOUS PRESIDENT

"3 Ways To Restore Government Contracts for Agile Services"

Case Study - CKW Group: Sourcing of a group Intranet Solution in 2 days via Lean-Agile Procurement

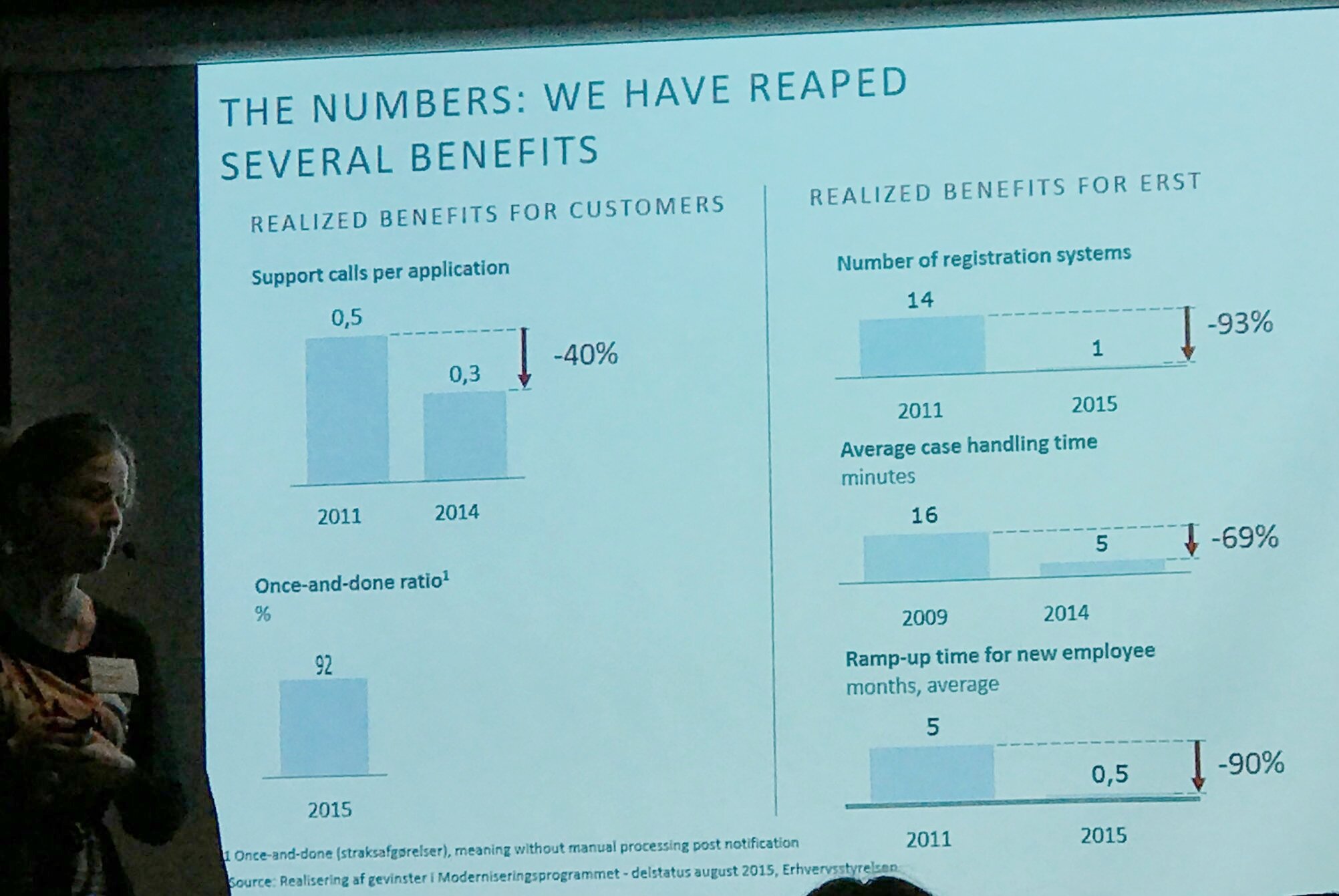

Procurement so far has shown that CKW must move faster and closer to customers in order to better meet their needs. So they decided to try Lean Agile Procurement (LAP) for the first time in order to procure a group intranet solution. With fantastic results, e.g. 400% increased time-to-market!

Thought leaders like Dr. Jeff Sutherland promotes Agile in his book “Doing twice the work in half of the time“ (1). Wouldn’t it be cool to increase time-to-market in procurement as well?-Free Download of our Article in “THE PROCUREMENT MAGAZINE”

Thought leaders like Dr. Jeff Sutherland promotes Agile in his book “Doing twice the work in half of the time“ (1). Wouldn’t it be cool to increase time-to-market in procurement as well?

No wonder agile is currently one of the top three strategic topics in corporate boardrooms. Case studies from all sectors and industries have proven that following agile principles and practices dramatically increases the timeliness and quality of business outcomes...

Find the whole article in "The procurement Magazine" 2018 / 05 (FREE Download)

Author

Shorter & readable Contracts - Disruption or just faster horses?

UK government lawyers have created a shorter, more user-friendly public sector contract to encourage smaller businesses (SMEs) to bid for £12m worth more easily. Is this really a disruption or just faster horses?

UK government lawyers have created a shorter, more user-friendly public sector contract to encourage smaller businesses (SMEs) to bid for £12m worth more easily. Is this really a disruption or just faster horses?

As reported in the supply management news 2 days ago the Government Legal Department (GLD) said Chris Stanley, a lawyer from its commercial law group, spent the past year reducing around 50,000 words of the existing Crown Commercial Service (CCS) contract terms to produce the new slimline public sector contract (20 pages long). Furthermore they

- made the contracts readable, even if you’re no lawyer could understand it

- like to become a benchmark for good business ethics by integrating some new corporate social responsibility obligations.

A lot of companies stopped bidding in public sector

Motivation of this was to encourage encourage smaller businesses (SMEs) to bid again for £12m worth more easily. From my own experience (compare with the blog post the facts about RfP) I can say, that a lot of companies stopped bidding in public sector as of too much effort/costs through a too complex bid process and contracting.

Is this a useful evolution or don't we need a revolution?

However, looking at this changes by the UK government with an outside perspective it’s looks to me like Henry Ford used to say.

“If I’d asked people what they wanted, they would have said faster horses.”

Don’t get me wrong. They had definitely the right intention and got a really good achievement from a legal point of view. However, I believe if we ask just the lawyers to simplify "there“ part we won’t get the full potential and just get faster horses instead of e.g. a „self-driving car".

The right people have to answer the right questions

For a real disruption we’ve to bring together all stakeholders of the whole value chain (customers, government, procurement, sales, lawyer, etc). Together we have to answer the „real“ questions, such as:

- why do we need a contract at all?

- how could we increase trust even before we’ve started cooperation?

- what can we do to increase time-to-market and so deliver business value to our customers earlier?

While development of lean-agile procurement we’ve asked this questions e.g. "what if we have to decide in one day?“ and together we've found applicable answers.

Learn more under Approach, we’re keen on your feedback.

Author

What could Business learn from Startups?

In Agile organisations, external partners are often treated as suppliers instead of partners, not recognising the opportunities they could potentially bring to their teams. In faster changing and complex environments, it will become a competitive advantage for companies to have fast access to an ecosystem of trusted partners with matching values and a fast contribution to goals. Join us this Friday as Mirko Kleiner will discuss what businesses could learn from startups in how they work with external suppliers.

I'd like to share the slides of my talk from the meet up "Future Friday" at Leiden University, the Hague.

Abstract

In Agile organisations, external partners are often treated as suppliers instead of partners, not recognising the opportunities they could potentially bring to their teams. In faster changing and complex environments, it will become a competitive advantage for companies to have fast access to an ecosystem of trusted partners with matching values and a fast contribution to goals. Join us this Friday as Mirko Kleiner will discuss what businesses could learn from startups in how they work with external suppliers."

Future Fridays

If you want to know more about the Future Fridays at the Center of Innovation, Leiden University check here

Slides on Slideshare

Impressions

Author

Slides from my Speech "Success Factor Agile" from Agile Bodensee Conference, Konstanz/Germany

Approximately 60-90% of all sales are in the hands of procurement, which is a key success factor for companies. At the moment, digitization is taking place, especially in the area of imple procurement. However, the latest study by the University of St. Gallen shows that there is no recipe for the effective procurement of complex products and services. Does agility offer a solution? - It is about billions and thus nothing less than the survival of suppliers and customers!

Abstract

Approximately 60-90% of all sales are in the hands of procurement, which is a key success factor for companies. At the moment, digitization is taking place, especially in the area of imple procurement. However, the latest study by the University of St. Gallen shows that there is no recipe for the effective procurement of complex products and services. Does agility offer a solution? - It is about billions and thus nothing less than the survival of suppliers and customers!

If we agile coaches draw an ideal organization, it usually looks like a network organization consisting of agile, autonomous cells. Up to now, our focus in agile transformation has been on the customer and to the internal organization. In the future, agility will cover the entire value stream and thus also the agility of our partners.

As external partners are often closely integrated into the agile organization they became an essential component of the value stream. However, many are still being treated as suppliers with a focus on a price as low as possible, instead of partners on equal terms with additional innovation power. In an ever more rapidly changing, more complex world, it becomes an integral success factor for a company to have quick access to an ecosystem of adaptive partners. Therefor we have to adapt our sales and procurement as well.

KEY TAKE-AWAYS

Please find below the most important key take-aways of the speech:

- the market is changing dramatically. Small vendors could stop production lines of big companies such as VW (27'000 Employees where blocked) and procurement was unable to react in time.

- new developments like e.g. 3D-Printing offer new possibilities to solve complex problems in development and production with fast delivery (Lead times of DAYS to WEEKS), so that it makes no sense to spend months for procurement any more

- for reaching true business agility companies need to create there own adaptive partner ecosystem. This will become a much bigger multiplier for business as today.

- the lean procurement canvas and lean-agile procurement have the potential for a disruption as the business model canvas and lean startup had for business development

- the lean procurement canvas is simple. Find an example in the slides

- The lean procurement canvas is the most LEAN agile contract right after a verbal contract

- there are success stories out there that sourced a new partner in 4 days instead of months, while the people that would work together evaluated each other in an agile approach.

Slides on Slideshare

Author

3D-Printed Aircraft Engine - Is your Procurement as agile?

This week GE released this great GIF of its 1,300-horsepower advanced turboprop (ATP) engine in which more than one-third of the components have been built through additive manufacturing, or 3D printing. The company is showing off its creation in real life at this week's big air show in Oshkosh, WI. In other words hardware development is getting more and more agile, is your procurement as agile?

This week GE released this great GIF of its 1,300-horsepower advanced turboprop (ATP) engine in which more than one-third of the components have been built through additive manufacturing, or 3D printing. The company is showing off its creation in real life at this week's big air show in Oshkosh, WI. In other words hardware development is getting more and more agile, is your procurement as agile?

Background

Already in 2016 GE reported the first 3D printed jet engine. They made a simple 3D-printed mini jet engine that roared at 33,000 rotations per minute.

In contrast to traditional machining methods that typically cut parts out of larger pieces to get to a finished shape, additive manufacturing uses lasers to fuse thin layers of metal on top of each other to build parts from the ground up. This advanced technique means less material waste and more complex parts that can be built precisely to optimize how they work inside a machine.

“This is not a matter of simply replacing one production method with another, but of reinventing the way aviation engines are conceived and designed”

"There are really a lot of benefits to building things through additive,” says Matt Benvie, spokesman for GE Aviation. “You get speed because there’s less need for tooling and you go right from a model or idea to making a part. You can also get geometries that just can’t be made any other way.“

As Joe Justice, creator of Scrum@Hardware, Scrum Inc. recently mentioned: „Thanks to the new technics it’s no problem any more in hardware development to build an engine (working increment) within one iteration!“. One iteration is by definition of scrum less than 4 weeks, modern teams usually use 1-week sprints.

Conclusions

If hardware development is getting that fast and flexible procurement has to adapt too. It’s predictable, that we will change our partners in a much more adaptive way as we'll do with the production method depending at the current customer needs. In other words we need to close the gab regarding speed (DAYS instead of MONTHS) and become as innovative in sourcing a new partner as the product development is.

Read more about how you could do that with lean-agile procurement

Sources:

http://www.ge.com/reports/reengineering-elevators-transform-21st-century-cities/

http://www.ge.com/reports/treat-avgeeks-inside-look-ges-3d-printed-aircraft-engine/

GE Made a Real 3D-Printed Plane Engine and Here's a Gorgeous Look at It

Does the RfP Process need a MAJOR Upgrade - Episode 3: RfP 3.0 'Request for Participation'

Looking back in the history of the RfI/RfP process we see, that it’s source was developed in another time at the end of the 19th century. Of course the new channels like phone, email, web, etc. allowed new possibilities and increased efficiency. However the core of the process stayed nearly the same. Do we may be need a major upgrade after almost 120 years?

Lets have a look at the RfP 3.0, the request for participation and how this improves competitive advantage of buyers and suppliers.

Looking back in the history of the RfI/RfP process we see, that it’s source was developed in another time at the end of the 19th century. Of course the new channels like phone, email, web, etc. allowed new possibilities and increased efficiency. However the core of the process stayed nearly the same. Do we may be need a major upgrade after almost 120 years?

Lets have a look at the RfP 3.0, the request for participation and how this improves competitive advantage of buyers and suppliers.

<< Previous blog post: Does the RfP Process need a major Upgrade? - Episode 2: The Facts

Please note: This blog posts is focusing just on the RfP process. We are aware of the fact that modern procurement is much more than this. We hope you enjoy another perspective!

“Lean-agile procurement reduces and distributes risk through incremental and value-added funding for improved business outcomes.”

In previous blog post we’ve learned, that the RfP 2.0 doesn’t work with complex tenders . What we all assumed is underlined with facts. We can’t predict, nor estimate the unknown and so we can’t specify the scope without creating waste. We would need so much time for investigation, that we already could start probing iteratively. Furthermore, we’ve learned to focus to the end user/customer needs, constantly validate those and look for a future-proof partner instead of a predefined solution. If we don’t reinvent RfP 2.0 fundamentally we might loose more and more potential partners interest and with that we’ll also loose opportunity for unexpected innovations and so a potential competitive advantage.

All this leads us to the conclusion, that we need a major upgrade of the RfP, the RfP 3.0!-An upgrade, that fosters collaboration and innovation. We call it „Request for Participation“. But how does it look like?

The thing with trust

The fundament of a partnership is trust and transparency. Have you noticed?-We’ve said partnership instead of relationship, that’s the first fine but big change with RfP3.0. In an ideal world we would just choose a partner and start probing iteratively. Unfortunately, our current culture and believes are not yet there. So we need something in between. The funny thing with trust is, it works in both ways. This often gets forgotten. In other words we need to establish trust and reduce risks for both sides (buyer and partner) at the same time. Therefor we can create sophisticated agile contracts, that describe and handle collaboration, scope, timing, budget, quality, warranty, etc. Personally, I don’t believe in that way and I’m more with Marco Zoppi.

“If the customer is starting to quote from the contract the cooperation has just found it’s end”

Sure, we have to manage the basics in a contract, no doubt. But I’m a strong believer in the good idea of men (theory Y, source 1) and we should not punish the majority, because of some few bad theory X cases from the past. By the way, Niels Pflägin said: "There are NO X-er by default, the system / organisation makes them behave like X-er".

Source: Douglas McGregor, Theory X/Y

Instead we should find lean and agile cooperation models and -contracts, that are fair and foster trust by e.g.

- risk share

- bonus / money for nothing, if we achieve the goal/s earlier

- work / fund just stages, with the option of an early exit at any time

- partnering / open books / joint venture

- etc.

So that the partnership stays adaptive instead of fixed. In my opinion, that’s true agile contracting!-But that’s another story.

Paradigm changes

Currently agile is the only approach we know, to deal with complexity. Its built in approach of build <> measure <> learn brings us iteratively towards the right solution. For the RfP 3.0 this means, that in complex tenders for innovation, business services, ICT, etc. it makes no sense any more to think off solutions (features / functions) or wants in advance. Instead we need to focus on the customer needs and with whom we could solve them best. All this is a creative development, that we only could achieve in a participative approach. The potential partner and all stakeholders from both sides (business, executives, lawyer, buyer, customer / user, developer, etc) need to be involved at once. YES, that means we do this all together in ONE room. This allows both sides to align with the customer needs, but also check if the partner is future proof, if we have a culture-/technical match (soft-/hard skills), etc. Only with this participative, creative development we will create real innovation and get first validations with the stakeholders available. Further advantage of this approach is speed (Time-to-Market). If we get all stakeholders in one room we can immediately decide and achieve results in DAYS instead of Months. We see this from other examples, like e.g. Design Thinking, Hackathons, etc. where time-to-market was improved with such a participative approach dramatically.

Acceptance of uncertainty

But how can we cope with this uncertainty of an „unknown“ solution (scope gets variable)?-Well, there are other disciplines out there, that face a similar challenge. If we think about business development they’ve used to write big business plans and switched over to the business model canvas (a structured page that describes a business model, source 2) and lean startup (an agile approach for early validation of the hypotheses with the customer, source 3).

The general advantages of a canvas are:

- it’s just one page and we have to focus to what really matters

- it’s a good overview / summary, that makes the essence transparent

- it makes things comparable

- it keeps us aware, that everything is connected and influences each other

- it’s a tool, that fosters collaboration and we could use every day to update our validations with customers /users

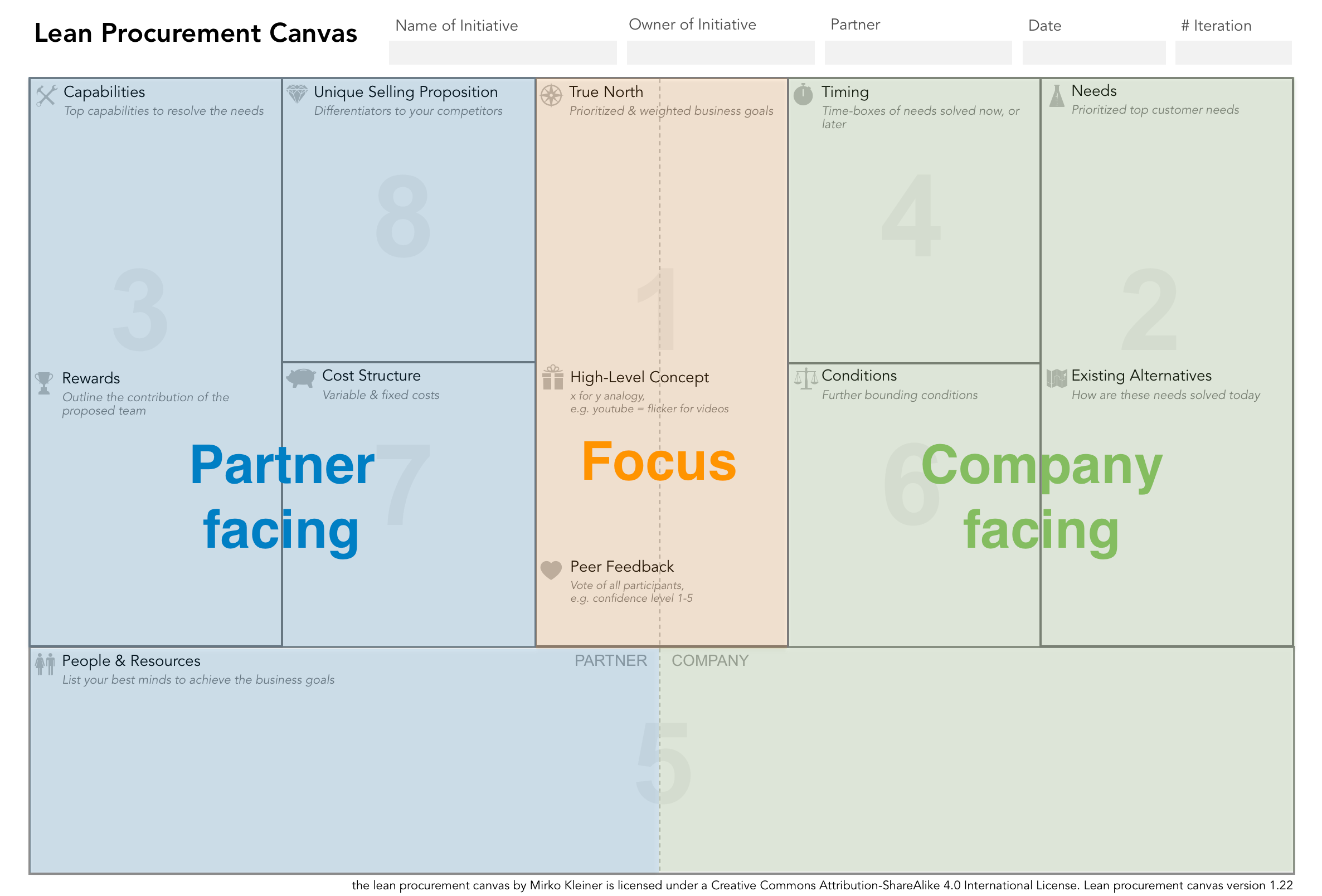

Source: Lean Procurement Canvas, Version 1.22 by Mirko Kleiner

What if we use the business model canvas for ideation and overtake the concept for procurement with RfP3.0?-We’ve created the lean procurement Canvas, that has basically 3 areas:

1. Focus - Strategic themes / goals (WHY we need this partnership)

2. Customer facing - Customer needs, timing, conditions, etc (WHAT we’d like to solve with this partnership)

3. Partner facing - Capabilities, USPs, etc. (HOW we’d might solve the customer needs)

After ideation with the business model canvas it’s very easy to overtake the strategy (WHY) and the customer needs (WHAT) and add the timing (WHEN), the people (WHO) and the conditions (WHERIN) within hours. With this we have the basic informations to start a participative event with one, or multiple potential partners. On this joint event we workout, whatever is valuable for us to decide starting an adaptive partnership. We could work out together more concrete customer needs and appropriate solutions, an agile roadmap of the next stage, etc. Basically we complete together the procurement canvas and decide.

“The lean Procurement Canvas is an agile Contract”

Start early, validate often

What counts for a business model and in more details for the customer needs counts also for a partnership. Instead of loosing time in non-valuable work we start as early as possible and constantly validate the joint achievements stage by stage and so the partnership. Therefor the lean procurement canvas becomes the tool for management of your adaptive partner ecosystem.

Conclusion

It turned out, that the lean procurement canvas can be used in all areas and industries, that have to overcome complex tenders, adaptive partnerships, etc. We get increased business value with RfP3.0 (increased time to market, reduced and distributed risk, incremental and value-added funding, improved business outcomes, etc). But for us most important, with the participative approach of RfP3.0 we’ve seen returning fun in the faces of all stakeholders!

Want to know more?

If you’ve got infected by the approach RfP 3.0 ‚Request for Participation‘ feel free to share your opinion and/or similar cases with us. More detailed information about the approach, success stories, the community, upcoming workshops and talks, etc. you’ll find under http://www.lean-agile-procurement.com - Stay tuned!

Author

Sources:

- Idea of men (Theorie x/y) by Douglas McGregor

- Business model canvas, by Alexander Osterwalder

- Lean startup, by Eric Ries

- Title image source: pinimg.com

Does the RfP Process need a major Upgrade? - Episode 2: The Facts

Looking back in the history of the RfI/RfP process we see, that it’s source was developed in another time at the end of the 19th century. Of course the new channels like phone, email, web, etc. allowed new possibilities and increased efficiency. However the core of the process stayed nearly the same. Do we may be need a major upgrade after almost 120 years?

Lets have a look at some interesting facts and experiences from the field handling complex tenders with the classic RfP process.

Looking back in the history of the RfI/RfP process we see, that it’s source was developed in another time at the end of the 19th century. Of course the new channels like phone, email, web, etc. allowed new possibilities and increased efficiency. However the core of the process stayed nearly the same. Do we may be need a major upgrade after almost 120 years?

Lets have a look at some interesting facts and experiences from the field handling complex tenders with the classic RfP process.

<< Previous blog post: Does the RfP Process need a major Upgrade? - Episode 1: The History

Please note: This blog posts is focusing just on the RfP process. We are aware of the fact that modern procurement is much more than this. We hope you enjoy another perspective!

“It’s funny how hiring practices have changed dramatically over the years, but pitching remains comparatively stagnant”

In the previous blog post we’ve learned, that the RfP 1.0 was initially developed at the end of 19th Century and one of it’s main purpose was to overcome the distance between buyer and supplier. Furthermore it worked good for simple until complicated tenders, where experts could exactly define and estimate the scope. In this blog post we wanna focus to complex tenders handled with the RfP 2.0. An example for a complex tender could be the evaluation of a new software product and -provider or a new marketing agency.

Just 20% of all features shipped are really used by customers

No matter of how we’ve evaluated and/or built a product, or a service it's important to understand, that just 20% of all features shipped are often used by our customers (Source 2).

Do you e.g. remember this fancy, but useless paper-clip assistant in ms office?-We need to accept, that we are guessing for the useful features during specification and we are again guessing in interpretation of these specs while creating an offer. That means the RfP 2.0 allows no real validation with the end user and creates a distance between buyer and supplier.

Engineers love the solution, this prevents innovation

In software projects we usually have engineers, that support the tender, on both sides (buyer/supplier). Engineers love engineering solutions and so specs are often describing already the solution (features and functions). In my practice I saw RfPs with hundreds of lines with functional specs. Nobody could tell us any more, who requested what and why.

“The observer influences the system and the system influences the observer”

This results in prevention of creativity, so that suppliers just delivered the requested solution.

KCOM reports in his analyses, that 70% of RFPs for consumer-focused projects forget or didn't require suppliers to explain how the IT project would improve the experience for customers. (Source 3)

Estimation of a complex Problem doesn't work

As a next important thing we have to consider, that we all are extremely bad in absolute estimation of a complex problem (Absolute estimation means the time to resolve a problem in hours). NASA reported, that absolute estimation of a complex problem can vary by 400% in both directions (Source 6). Beside this fact we should accept, that while solving complex problems the scope gets variable, while on the other hand we could fix ressouces/costs, time and quality.

“scope = f(time, quality, ressources)”

Let me tell you a story about. Once we’ve got an RfI with just 5-10 rough bullets. The buyer asked us for a first guess. We roughly estimated based at our experience and the expected team size/cost per month multiplied by time and got CHF 1.7 Mio. As our engineers went through all the detailed specifications of the RfP 2.0 the total estimation was CHF 1.75 Mio. This happened a lot to us and we got the feeling, that we’ve lost 3 more months again. In this time we couldn’t deliver value towards the customer and may be lost the window of opportunity.

RfP 2.0 is expensive

Going through a complex tender is expensive for buyer and supplier. I know from my own experience, that we’ve invested e.g. in complex e-commerce tenders with a spent volume of several millions 5-6 FTE’s over a period of 2-3 months. This is equal to CHF 150-250k investment for a single pitch, expenses not included.

“Complex tenders e.g. in IT usually takes us 3-6 months and a lot of effort in the procurement as well as in the business”

Talking with several CPOs and procurement organizations we’ve found out, that preparation and execution of a complex tender needs a similar effort at buyer side. The thing is this costs and the even higher costs-of-delay usually are not calculated in TCO. But this is another story.

Are we hiring an agency’s past or future?

Forbes wrote about the RfP2.0 in context of hiring marketing agencies, that it might give a rough idea of an agency’s past accomplishments, and these can inform somewhat of what’s ahead. However, we’re not hiring an agency’s past, we’re hiring its future. And that future is more likely to be a reflection of an agency leadership’s vision, the people it hires, and their willingness to embrace what’s coming rather than preserve what’s been. (Source 4)

“You’re hiring for the future, you’d want to know that they are prepared for it.”

We’d want to know if they have a clear sense of the new consumer, and the technologies and platforms that make listening more important than talking. A forward thinking leadership should have a pretty good point of view about how social media, technology, and the migration away from interruptive messages are changing communications.

About that topic KCM’s report showed, that a fifth (21%) of RFPs were for projects to update restrictive, non-compliant or even failing legacy technology, but only half of these sought innovation from potential suppliers and only 17% requested a future-proof proposition (Source 3).

Do you participate in RfP’s, the agency perspective

From my own experience and the investment a RfP 2.0 needed we’ve rarely chosen where to pitch. In majority of the cases we declined as we didn’t saw chances to win, had no connections to the customer, or any other USP.

“We totally omitted public tenders, that have to follow RfP 2.0 and only looked for the lowest price by law.”

“Brands are not hiring agencies to create perfect RFP responses that dazzle the brand managers. Rather, brands (should) want to hire an agency that will create unique communications that dazzle audiences. So, judging an agency by its ability to fill out an RFP is testing for the wrong talent. 5)”

“We rarely participate in agency-search RFPs. We’re against spec pitches but might respond to a request for information about Velocity. Our process depends on a lot of pretty intensive input. Pitches that ask for our ideas based on very little information are unlikely to generate great work. And they take a lot of time and effort that our current clients are essentially paying for. 5)”

If you’d google RfP you’ll find much more similar statements like this. We believe it’s a pity, that a process prevents us from more innovation and good partnership.

Conclusion

Applying RfP 2.0 for complex tenders doesn’t work. We can’t predict the unknown and so we can’t specify the scope without creating waste. We would need so much time for investigation that we already could start probing iteratively. If we don’t accept this we will loose a lot of time, effort and loose may be the window of oppertiunity. This extra costs we need to balance with the more trust we get and add this costs to our calculations of TCO. In complex tenders we should focus to the end user/customer needs and look for a future-proof partner instead of the solution only. This can only happen if we include all stakeholders like e.g. the end customer, the business and the potential partner and bring them together. If the process fosters collaboration and innovation more suppliers might get interested to participate in competition again.

All this leads us to the conclusion, that we need a major upgrade of the RfP, the RfP 3.0!

In the next Episode

Stay tuned, in the next blog post we present you a summary how the RfP 3.0 -the Request-for-Participation- could look like!

>> Next Blog Post: Does the RfP need a MAJOR Upgrade - Episode 3: RfP 3.0 -the Request-for-Participation

Author

Sources:

- Title Image source: Cat

- Standish Group, 2013

- KCOM, a communications and IT services provider, has carried out a detailed examination of RFPs it received over the past 18 months for strategic IT projects.

- Forbes.com

- 6 New Reasons to Kill the RFP: Find Innovators, Not Commodities

- Cone of uncertainty, NASA's Software Engineering Lab 1990

- Image Source paper-clip

- Huffington Post - is the RfP Dead?

- The suppliers perspective

Does the RfP Process need a major Upgrade? - Episode 1: The History

Looking back in the history of the RfI/RfP process we see, that it’s source was developed in another time at the end of the 19th century. Of course the new channels like phone, email, web, etc. allowed new possibilities and increased efficiency. However the core of the process stayed nearly the same and struggles with increased demands of complex orders. Do we may be need a major upgrade after almost 120 years?

Lets first look back in history, how it come to the todays RfP Process.

Looking back in the history of the RfI/RfP process we see, that it’s source was developed in another time at the end of the 19th century. Of course the new channels like phone, email, web, etc. allowed new possibilities and increased efficiency. However the core of the process stayed nearly the same and struggles with increased demands of complex orders. Do we may be need a major upgrade after almost 120 years?

Lets first look back in history, how it come to the todays RfP Process.

Please note: This blog posts is focusing just on the RfP process. We are aware of the fact that modern procurement is much more than this. We hope you enjoy another perspective!

History

Despite that people have been trading since ancient times procurement is a relatively new discipline and was unknown before 1800. One of the first mentions is from 1832 in Charles Babage’s Book On the Economy of Machinery and Manufactures. He points to the need for a ‘materials man’ in the mining sector, who selects, purchases and tracks goods and services required. Before, there were just local markets with low competition. Everybody knew each other and came e.g. to the local blacksmith and made his order for a new pick in person. The products were highly individual and hand made.

During the Industrial Revolution, procurement solidified its importance. Marshall Kirkman’s 1887 book The Handling of Railway Supplies - Their Purchase and Disposition, detailed procurement’s strategic contributions to the railroad industry, specifically in acquiring goods from developed parts of the country and bringing them south and west. In other words the markets developed further across a country, there were some first bigger players, but still low competition. Focus of the industry was on standardization and mass production of simple to complicated products. The suppliers were not known any more in person, so that the tenders were published in news papers (Request for information) and the suppliers sent there proposals by post. The RfI/RfP process was born (let's call this the RfP Version 1.0, or short RfP 1.0).

Grafic about historic development of procurement inspired by the graphic Komplexitoden from Nils Pflägin, 2017

Today, in the age of information, new technologies continuously evolve procurement. The digital revolution started with the internet, email and the web in the late 20th Century. This development was continued with E-procurement solutions, reverse-auctions, etc. to this day. Everything underlies the goal to make the RfP process more and more efficient and lean (RfP 2.0). This is necessary, then in the mean while the markets got globalized, the competitors are in a high competition and the customer demands got highly complex.

Conclusion

RfP 1.0 was developed in a time without internet, where the buyer and the supplier didn’t know each other and a direct collaboration was hard, or too expensive. It worked fine for simple and complicated orders. As those requirements could be described, understood and estimated by an expert. With RfP 2.0 we still follow the same basic approach from the 19th century to this day. We just applied modern, digital tools to it and got more efficient. However complex tenders, like e.g. in IT, are still taking us months and with RfP2.0 we loose the opportunity for creative solutions and innovation.

Is the sole focus on efficiency enough to cope with the current and future complexity of market and customer requirements?

In the next Episode

Stay tuned, in the next blog post we'll present you some facts. We will talk about some statistics and experiences from the field handling complex customer requirements with the classic RfP process.

>> Next blog post: Does the RfP Process need a major Upgrade? - Episode 2: The Facts

Author

Sources:

- Historie summarized from blog post by Mike Nolan | SourceSuite.com

- Grafic about historic development in from Komplexitoden by Nils Pflägin

- Cat image Image source: https://awritersden.files.wordpress.com/

Success Story POCathon@CSS Insurance - A Participative Evaluation in just 3 days

If you're wondering how a big room evaluation day (Step 3 of 4 in lean-agile procurement) could look like read this awesome interview with Konrad and Dominik about their custom implementation at CSS Insurance called "POCathon". CSS is one of the largest health insurers in Switzerland. For there complex evaluation of a software service provider they've invited 4 providers and put them all together in one room for 3 days. At the end of these 3 days they were able to decide with whom of the service provider they will continue agile delivery at the next day!

If you're wondering how a big room evaluation day (Step 3 + 4 in lean-agile procurement) could look like read this awesome interview with Konrad and Dominik about their custom implementation at CSS Insurance called "POCathon". CSS is one of the largest health insurers in Switzerland. For there complex evaluation of a software provider they've invited 2 providers and put them all together in one room for 3 days. At the end of these 3 days they were able to decide with whom of the service provider they will continue agile delivery at the next day!

“The POCathon fits perfectly into lean-agile Procurement and we will use both in combination again.”

Who are you guys and what is your job with CSS insurance?

Konrad Durrer: I have been working in IT for 35 years and was always looking forward to learn new things. After writing stock market applications on large systems, I entered the first ETH course of studies in Computer Science. I then worked in industry and for the governance before joining CSS Insurance. I'm now an architect and technology consultant. In leisure time, I run marathons and enjoy life. Konrad was responsible for the evaluation and is co-initiator of the approach POCathon.

Dominik Liebmann: I'm an API management and integration consultant at ipt AG. My focus is on simplifying business processes. Since my first company at the age of 16, I've been working with IT-supported business processes and worked for many companies (SAP, IBM, Bison Schweiz AG) in Germany and abroad (Russia, China). I personally spend my time either at the local stove or go for mountainbike races. Dominik supported CSS as an external consultant and is co-initiator of the approach POCathon.

You are the initiators of pocathon, what is it exactly?

Konrad & Dominik: The "POCathon" is a combination of the words Proof-of-Concept (POC) and Hackathon and is intended to combine the advantages of both approaches. With a POC you want to test the cooperation with a new partner and its services and / or products. With a Hackathon it is very quickly possible to achieve many learnings by simply putting the right people together and try things out by implementing them. The POCathon starts, when the customer needs and possible providers are already known. It allows to evaluate them jointly in a participative process with an ultimate decision. We see the application area of POCathon independent of the industry and the topic, as long as this has a certain complexity.

Image: (c) 2013 by Sebastiaan ter Burg (Amsterdam Hackathon)

This sounds very extraordinary, even disruptive. How did you get it?

Konrad: Classical POCs are intransparent, partially unfair and and it is not easy to differentiate between product, service and partner. Also, the lead time is incredibly high (weeks & months) and thus the investment massive. We were looking for a faster, more lean way of a competitive evaluation and got inspired by lean-agile procurement (LAP).

Dominik: In LAP, we particularly liked the participative idea, so the people, who are also concerned about it, are placed in the center and get empowered to decide for themselves. This has the advantage that not only the product, but also the partner (soft / hard skills), their way of thinking and working, as well as the cooperation and the ability to deliver can be tested. If the stakeholders are able to participate in this short period of time, they also get a deeper insight. Of course the speed, or time-to-market, was also very exciting to us. Beside that I totally agree with Konrad, that classic evaluations and POCs are partially unfair. Especially as these are done sequentially and it's in our nature that we remember the last provider the best and the 1st the worst.

What made you decide to run a POCathon just for this project?

Konrad: On the one hand there was the pressure of time and the complexity of the business needs. On the other hand the project offered itself, it had clear bounding conditions, the procedure was in our decision-making competencies and the evaluated products were roughly comparable. We therefore looked for further criterias and also wanted to involve the users directly in the decision. Furthermore the details for the POC were already well prepared through the preliminary work.

Dominik: Due to the technical background of the project, all stakeholders were from IT and were tangible for us. The fact that we wanted to involve them in the evaluation became mainly beneficial. Likewise, the providers were open to the procedure too.

“What used to take WEEKS & MONTHS now only takes DAYS!”

How did the pocathon work in practice, can you explain a little bit?

Konrad: First of all the product vision (why) and the business needs (what) of the POCathon were presented to all 2 invited providers. This set the frame, so that the 2 vendors could start implementing their solution (HOW) self-organized, by taking one business need after the other from the prioritized backlog. It was the idea that we have 2 implementations in parallel similar to a competition between the 2 providers.

Dominik: Therefore we basically had an iteration each day. In the morning we made a planning and at the end of each day the results were presented in a review session to the real users. They assessed the technical integration/solution and gave direct feedback to the vendors. We facilitated the process throughout the day and answered questions instantly. In doing so, we also experienced surprises such as when a vendor was apparently behind the schedule but then catch up and delivered in time until the next demo. In addition to that, the users got to know the products and the providers personally in the day-to-day collaboration and this also formed interpersonal preferences. An important aspect of our approach, where usually is not enough time for.

What do you recommend any followers?

Konrad: We had made the preparation of the requirements and / or the preselection in a classic approach. Today, based on the huge success of the POCathon, we would work this phase in a participative process too using the lean procurement canvas and lean-agile procurement. This would allow us to faster classify the offered solution and its intermediate results faster.

Dominik: The POCathon was an experiment. Accordingly, we could still improve a lot, for example the top management could be invited too, end users should constantly participate during the POCathon (they were just for the demo present), the lean Procurement Canvas incl. an agile roadmap could be developed together with the providers, etc. Furthermore, you shouldn't under-estimated scaling effects the more providers get invited.

Where are you today in the project and did you achieve what you hoped with the pocathon?

Konrad: The selected product is in productive use. The users were very motivated by the participative process. You just can not underestimate this. All-in it was a big success for us from the buyer perspective!

Dominik: From the approach point of view we over-achieved our biggest expectations. We could speed up time-to-market, participation of end users and made finally a decision.

How was the feedback from the organization or the suppliers?

Konrad: From both sides very positive, which has surprised us. Due to the daily reviews in the evening, a high identification of the end user with the product could be achieved. We believe this is because they have become part of the evaluation process from the start. We do not recognize the usual discussion that product B would have been better.

By the way, all the providers were paid for their expenses (3 days). This was important to us, since they all delivered business value during the POCathon, one provider contributed already to our current solution and through the others we got important new ideas, learnings and feedbacks. Usually, the winner is willing to provide a special rabat of the amount we invested.

Dominik: I think such an approach is in the interests of all parties. From the point of view of the buyer, all stakeholders as well as the project team members themselves are involved into the decision. From the point of view of the providers this approach gave them the chance to present themself in a completely different quality, with a much less investment of time and ressources. In total, the end user benefits as well, since he gets business value delivered faster, more effective, the procurement process gives room for innovation and becomes less expensive.

Surprisingly the providers even liked the competitive approach being in the same room with their competitors :-)

How does it go on, will you use lean-agile procurement or the POCathon for further evaluations?

Konrad: We see a mutual value both. LAP can be made with a larger number of providers do workout the WHY/WHAT and a POCathon covers the solution (HOW). The POCathon complements LAP perfectly and we will use this in combination again.

Dominik: Amazing was retrospectively what we have been achieved in only 3 days. Imagine if the preparation work and preselection could become similarly effective by the combination with LAP. This will in our opinion disrupting procurement: What used to take WEEKS & MONTHS now only takes DAYS!

Thanks for the interview and FOR SHARING OF THIS AWESOME STORY!

Source: CSS Insurance AG, Switzerland 2017

Interviewer & Author

Going Digital, Procurement in Kanton Zug

Repeating last year’s very successful event, CIPS-Switzerland is teaming up with the Technologie Forum Zug and the Economic Promotion team of the Kanton Zug for this special Procurement & Supply Chain (P&SC) event. Speakers include leaders from companies with regional or global headquarters in the Canton around the theme of “Going Digital, flowdays took place with a booth to represent the disruptive approach lean-agile procurement.

Repeating last year’s very successful event, CIPS-Switzerland is teaming up with the Technologie Forum Zug and the Economic Promotion team of the Kanton Zug for this special Procurement & Supply Chain (P&SC) event. Speakers include leaders from companies with regional or global headquarters in the Canton around the theme of “Going Digital, flowdays took place with a booth to represent the disruptive approach lean-agile procurement.

Procurement in Kanton Zug”. It is well known that Zug is fast emerging as a leading P&SC cluster in Europe. In addition to hosting drinks and snacks to facilitate participant networking – several Zug-based Procurement Service Companies with be available for follow-up discussions (including Consultants and Headhunters).

The speakers where:

Mr André Wismer, Biogen Switzerland AG, Product Specialist

André Wismer holds a Bachelor degree in BA with a focus on International Management and Economics (IM&E) from the Lucerne University of Applied Sciences and Arts (HSLU), Switzerland, and an MSc in Logistics and Supply Chain Management from Cranfield University, UK. His presentation at this CIPS event was about his research obtained during his MSc thesis project and provide interesting insights based on Swiss based companies.

Conclusions: Find his main findings below:

Mrs. Leong, Cecilia, Olin Corporation, Head of Regional Purchasing EMEAI & APAC and Global Business Excellence

Head of Regional Purchasing EMEAI & APAC and Global Business Excellence Leader with Olin Corporation, Cecilia has throughout her career provided the transformational leadership. This has enabled operations to become effective and efficient commercial organizations. She has excellent cross-functional global program and project management skills, and has built a year-over-year portfolio of achievements includes million-dollar revenue and profit gains, operational improvements and innovative solutions that set the stage for both immediate and long-term growth.

Conclusions: Before introducing a new, expensive system for procurement check what your CRM could serve you. Cecilia showed, that the roles and the requirements towards a system are quite similar for a marketeer and a procurement manager.

Mr Adrian Doyle, Amgen Europe, Global Strategic Sourcing, Head of Region Europe

Having over 17 years of procurement experience in the pharma industry Adrian has a wealth of commercial category, regional and global sourcing expertise. Starting in the UK with GlaxoSmithKline, about 4 years ago he moved to Switzerland to join Amgen’s Strategic Sourcing leadership team.

During the Networking and Interaction session flowdays was present to introduce the procurement experts into lean-agile procurement. The echo was awesome, as we've got even 5 feedbacks like this:

“lean-agile procurement is a real disruption, you should have been talking about before”

a special thank to John Everett, Branch leader at CIPS and organizer of the event!

The agenda was:

17.30 Event Registration and Refreshments

18.00 Event Start and Introduction

18.05 Mr Andre Wismer, Biogen Switzerland AG - Digital Transformation of Swiss Procurement

18.35 Mrs Cecilia Leong, Olin Corporation - Procurement can be early adopters

19.05 Mr Adrian Doyle, Amgen Europe - Procurement enabling digital engagement

19.30 Networking and Interaction with Zug based companies including:

Customer Value Management GmbH

EMEA Recruitment GmbH

Deloitte Consulting AG

Flowdays

BSMA-Europe

Performex Consult GmbH

21.00 Event Close

Drinks and snacks will be provided during the newtworking session.

Good Practice in procurement of business Services & Results of the Performance Excellence Study 2016

The conference about good practice in procurement of business Services in Bern, organized by procure.ch and University of St. Gallen (UNISG) Research Institute for Logistics Management brought together an amazing group of pan-european/-industry procurement experts. The UNISG presented their Results of the Performance Excellence Study 2016 and the top performer an open and honest insight about their current state in procurement. I really hope this kind of event will be continued!

The conference about good practice in procurement of business services in Bern, organized by procure.ch and University of St. Gallen (UNISG) Research Institute for Logistics Management brought together an amazing group of pan-european/-industry procurement experts. The UNISG presented their Results of the Performance Excellence Study 2016 and the top performer an open and honest insight about their current state in procurement. I really hope this kind of event will be continued!

After a short introduction and presentation of the results of the performance excellency study 2016 by Erik Hofmann and Martin Händel (both UNISG) the stage was given to the top performers of the study. They shared there good practices, there current challenges and believes about trends and upcoming practices. As the presenters of the top performers were cross-industries and cross-functions it gave a very good overview of the current status of procurement of business services. To be continued!

The following a summary about the most impressive talks held and my personal view on most important lessions:

Introduction

-- Prof. Dr. Erik Hofmann, Director University of St. Gallen (UNISG) Research Institute for Logistics Management

- Results: in 2015, more than 73% of Swiss workers were employed in the service sector. Depending on the branch, a share of up to 80% of the total purchasing volume is possible. A complexity driver is the individual tailored business service. Although the importance of business services has been noticed, the majority of purchasing managers still struggle with a consistent procurement of services in comparison to goods purchasing.

- The most important lessons: There is a lack of specific evaluation tool and approaches for purchasing business services, outcome. It’s quality depends not only from partner/supplior, but also on customer itself. Good practices to measure success of business services delivered are not yet well established. Focusing more to customer/user feedback over budget/cost will become more important in the future.

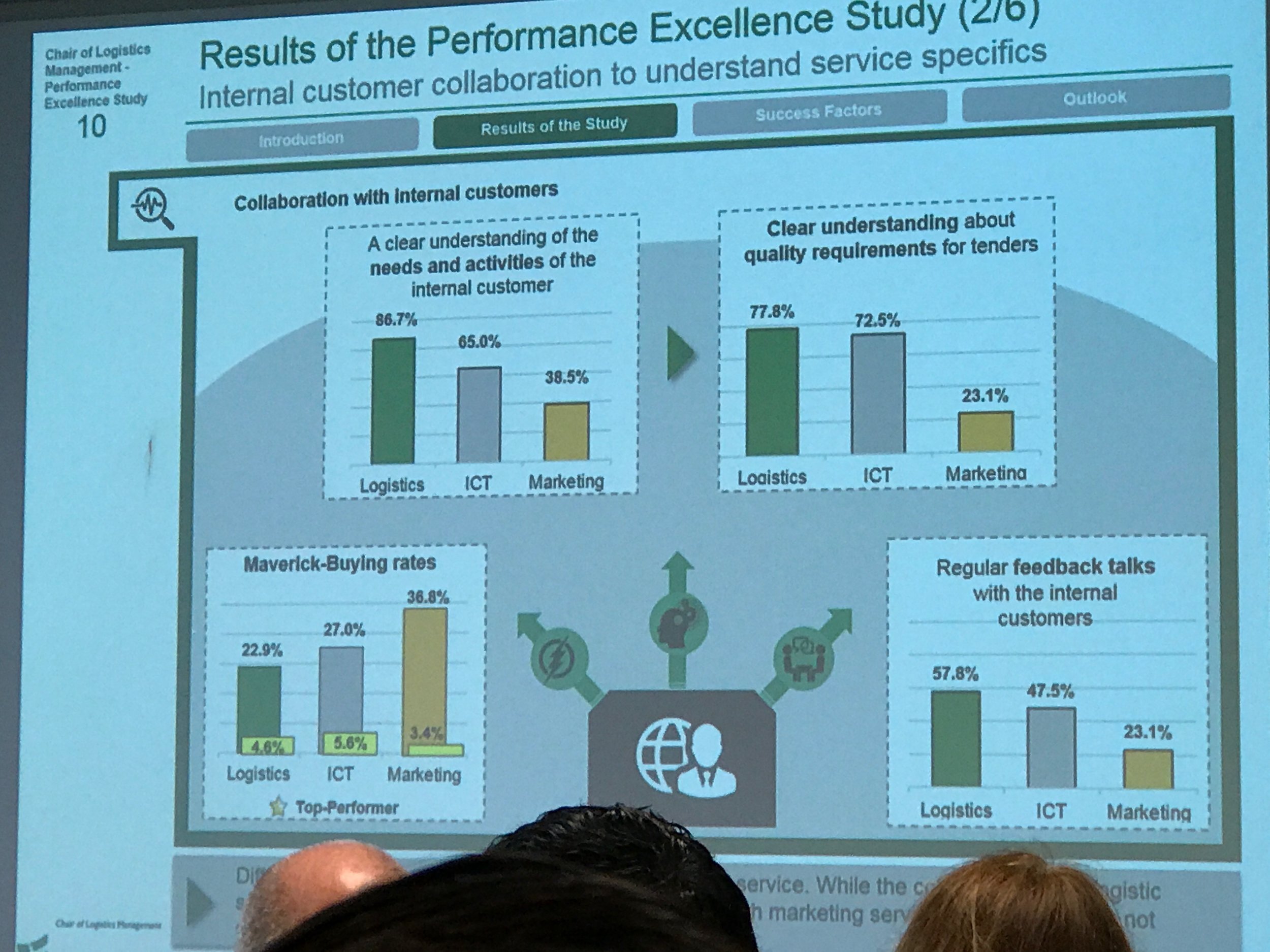

Results of the Performance Excellence Study 2016

-- Martin Händel, Project Manager UNISG

- Results (just a subset): There was no representative study in area of procuring of business services available yet. In other words this seems to be a undefined field. Focus of the study was set to 3 business areas „Marketing“-, „Logistics“- and "ICT“-services. It turned out that depending at the business service area the most relevant evaluation criterias are different, even within one area depending at service evaluated. Because of complexity there are no specific business service evaluation tool available yet. External factors and trends like digitalization, industry 4.0 will increase complexity even more. While area of logistics was the best of the three, area of Marketing has biggest potential for improvement. The interviewed companies showed, that there is room for improvement in area of partner collaboration, transparency, monitoring and outlook. It's fact that the customer and user needs are often insufficient known. This is valid for external as well as for internal customer/partner relationships.

- The most important lessons: Services will increasingly be procured together with products (hybrid services) and because of that complexity and the need to increase knowhow in procurement and products will increase more and more. This can’t be handled by procurement alone in the future. This will become more of a team effort, or even an empowerment and enablement of the experts that are the nearest to the customer need. Furthermore the service provider will have to tightly integrate with the customers value stream. Most important learning was that the researcher found is no pattern to procure business services nor a tool yet, that supports it.

Order the Performance Excellence Study 2016 via procure.ch

Insights by the top performers of the Performance Excellence Study 2016

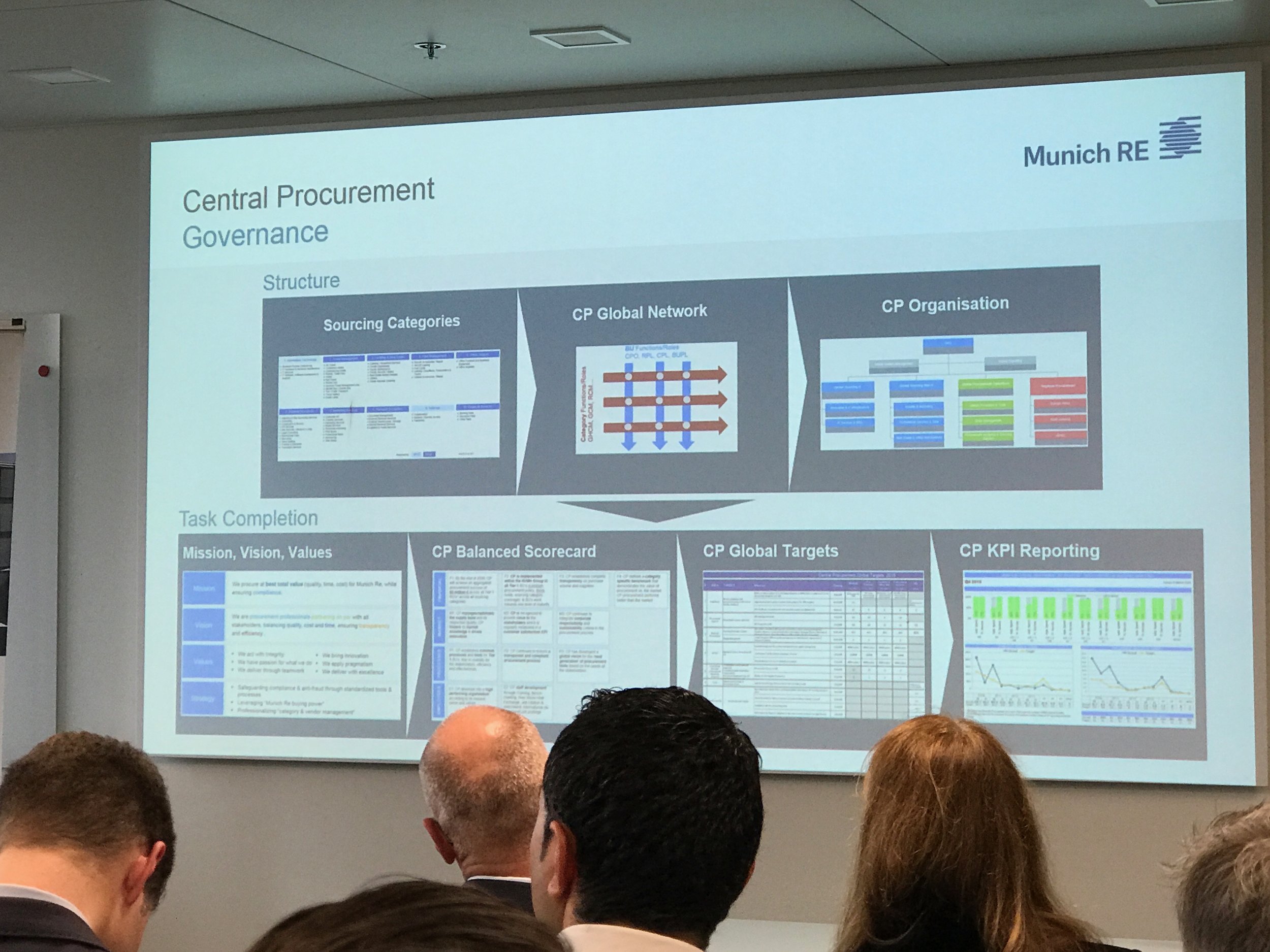

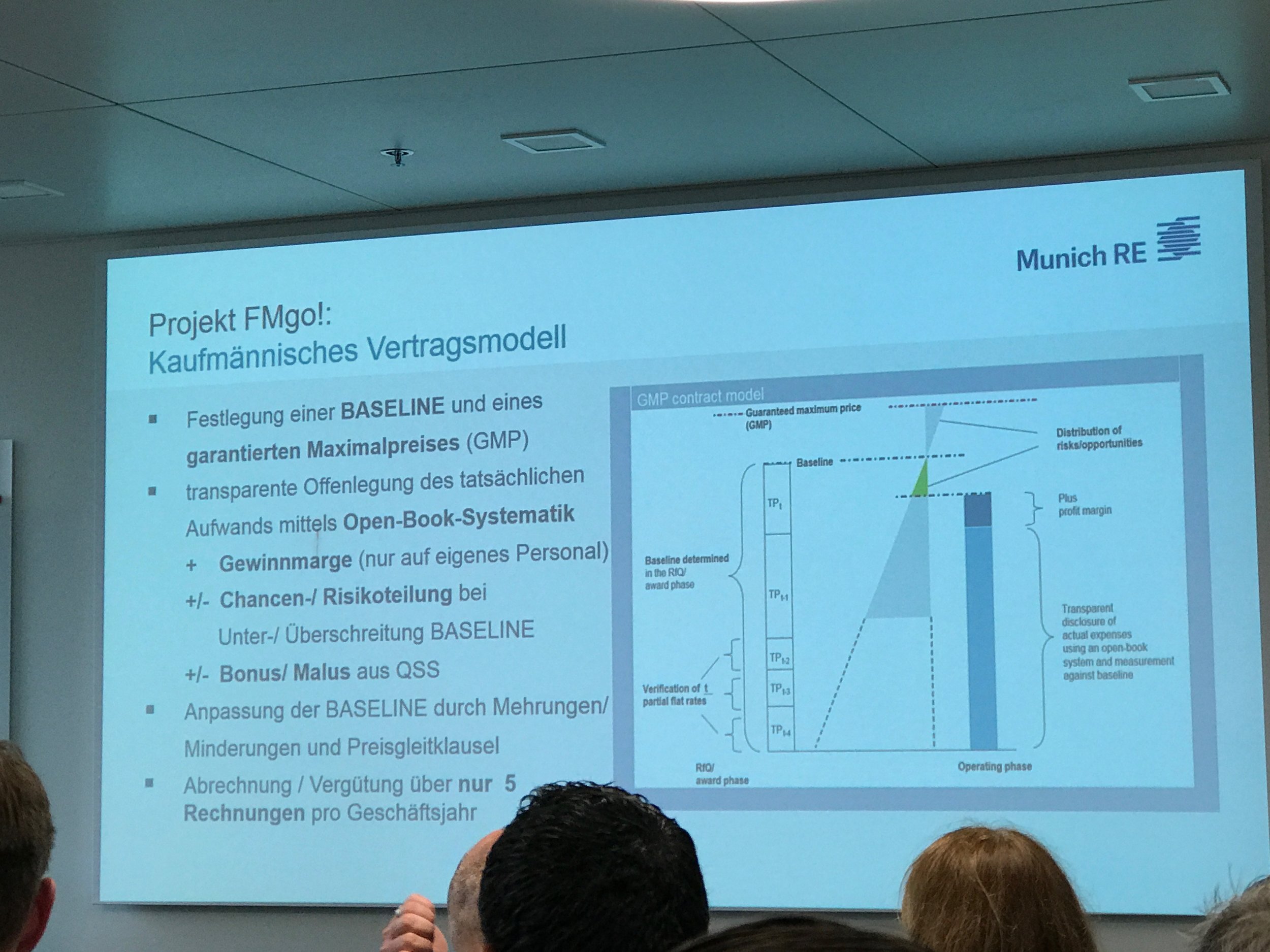

Value-based Procurement at Munich Re

-- Bernhard Bundlechner, Global Head of Category Management, Munich Reinsurance AG

- Results: Till 2001 money was no issue at Munich Re. These days situation and market has changed. Munich Re is more and more an investor in start-ups as well. It has it own innovation scouts, labs, ideation events and corporate partnering (ecosystem). Therefor it’s for them more valuable to find the right service partner than the cheapest. That’s why they’ve introduced for more than 80% of the procurement requests digital solutions. Unfortunately these cover just 2% of the order volume. For more complex procurement Munich RE often uses value based procurement. The example shown was about the outsourcing of the whole facility services in a value based approach. This partnership lead to much less management overhead (just 5 invoices), more innovation (e.g. is partner motivated to introduce new facility to save maintenance costs), increasing quality of the service (by an overall bonus system), more loyalty and motivated employees (as they were empowered and got incentivized as a team depending on the whole success) and a good partnership (as risk was shared and margins were defined long-therm).

- The most important lessons: Partnering or value-based procurement needs a lot of trust and is depending at the given company culture of both customer and supplier. Building this trust by e.g. having open books is not possible in every case and there is a trade-off between having a sustainable partnership and a locked-in situation. However, looking with an agile mindset at this cooperation model it seems to be the most fair and promising approach for procurement of business services. Nevertheless trust and transparency needs a honest communication, monitoring, feedback loop, continuous improvement

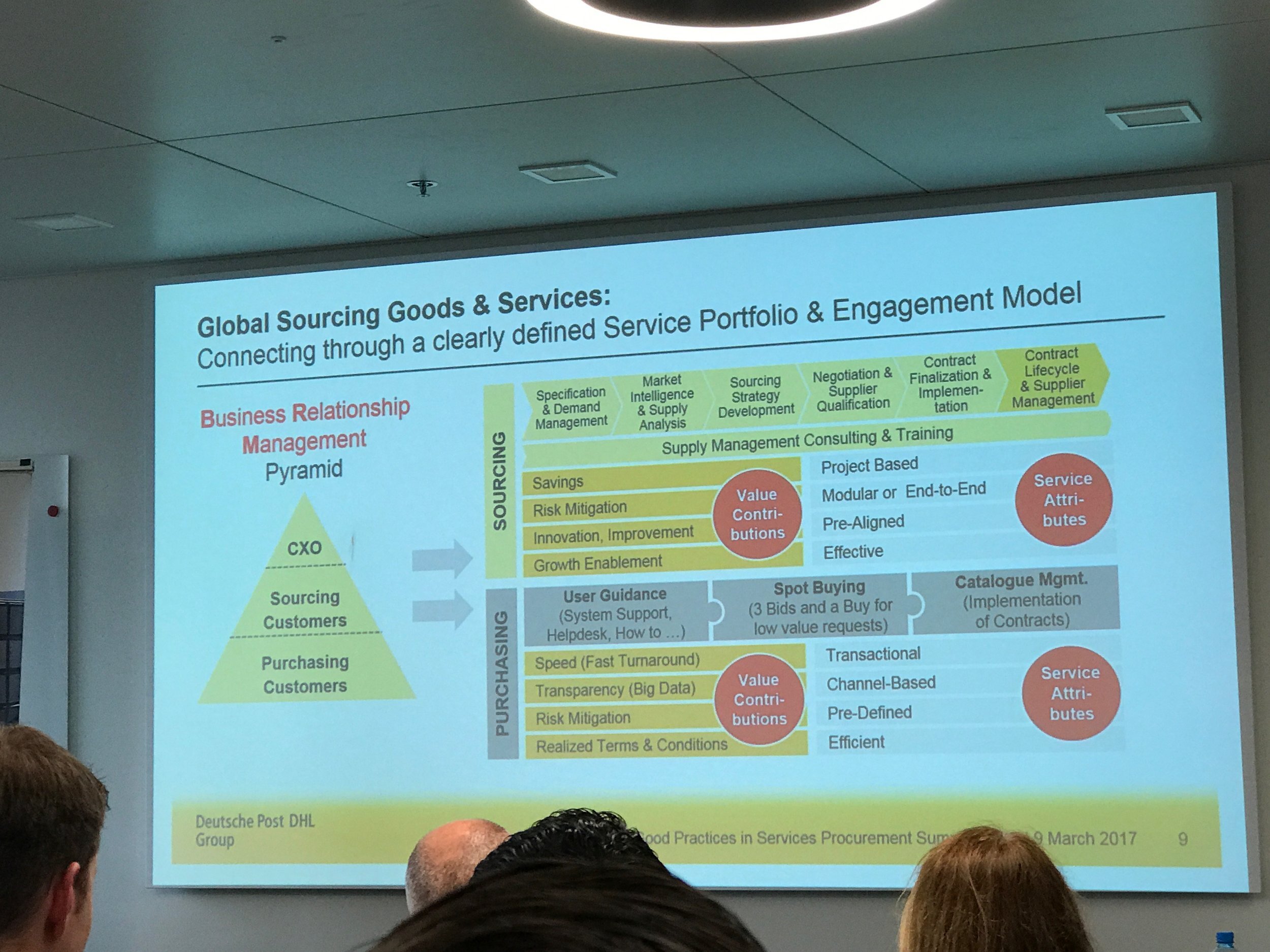

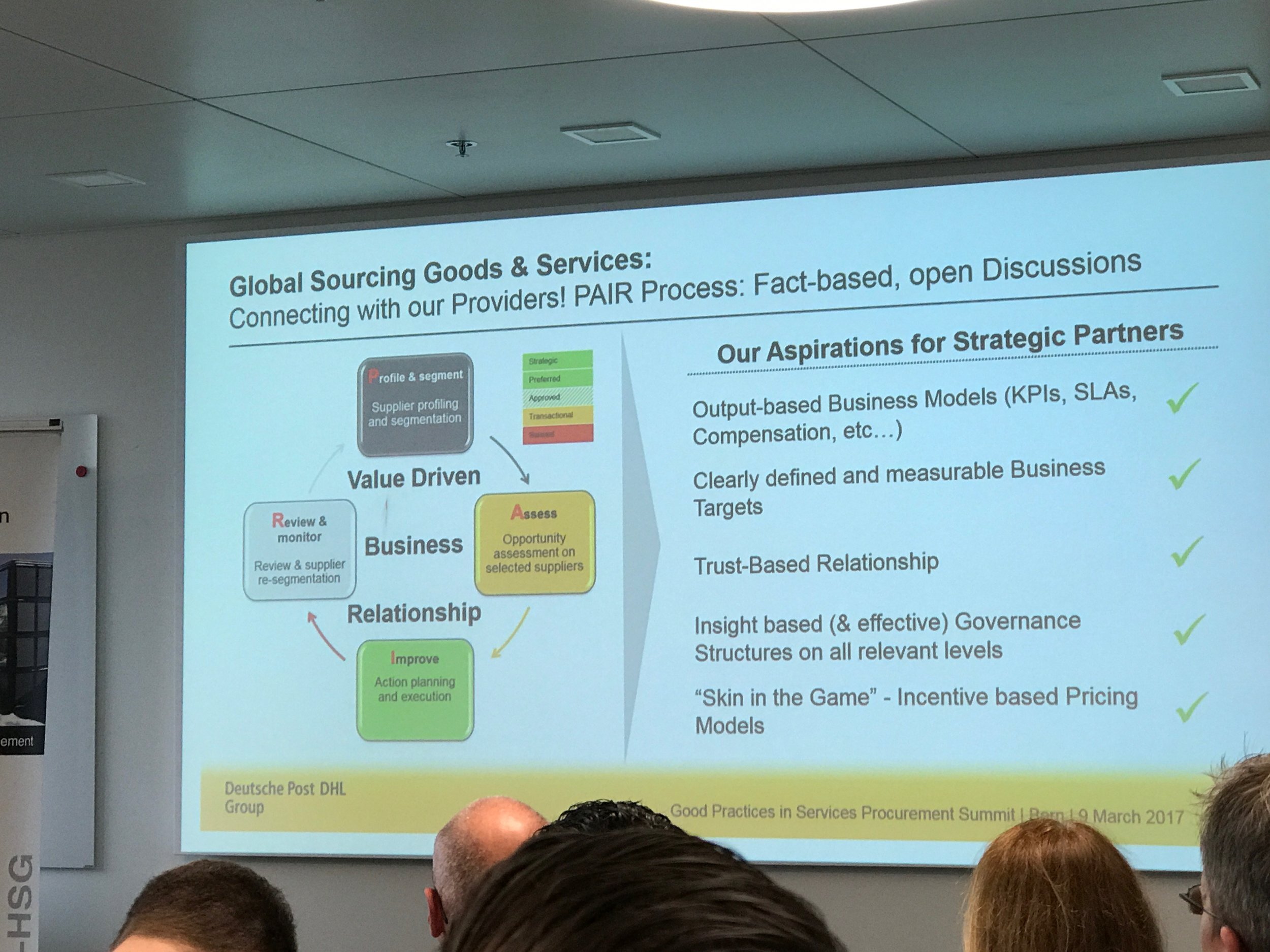

Connecting Differently! Service Procurement@Deutsche Post DHL Group

-- Dennis Böing, Head of Global Sourcing Goods & Services Deutsche Post DHL

- Results: With roughly 500k employees Deutsche Post DHL is a global player and one of the biggest employer in the world. The major challenges in area of global goods and services are the raising labor costs and total costs of ownership (TCO). As well as the increasing complexity (>100k Suppliers and >12 sites) and the adherence to (stricter) laws, policies, rules & guidelines. Because of the incredible amount of transactions every minute DHL had no other choice as to focus to automatization and big data/analytics from early days on. With the strategy 2020 focus.connect.grow DHL went on the journey from a unsatisfying supplier experience (complex organization to deal with, primary focus on squeezing costs, not enough sharing of strategic planning) to an aspiration for the future (a joint learning curve toward strategic partnerships, right balance between quality/costs, optimization of process on both sides). The challenges in procurement are approached by connecting differently with internal stakeholders, external (strategic providers), the markets trough a service portfolio and engagement model.

- The most important lessons: Nevertheless DHL has 470 FTE in procurement it’s impossible to handle all 100k suppliers manually. That lead them to categorize and connect differently. In other words they've set focus. In these highly valuable collaboration they’re also in progress changing the culture of cooperation. Fairness, sustainability, leadership and other words were told several times and as those are part of the strategy they become more and more important for procurement as well. This investment is done similar to other top performers not just externally, but internally as well. Changing the mindset and development of the employers skills becomes more and more an obvious pattern for procurement

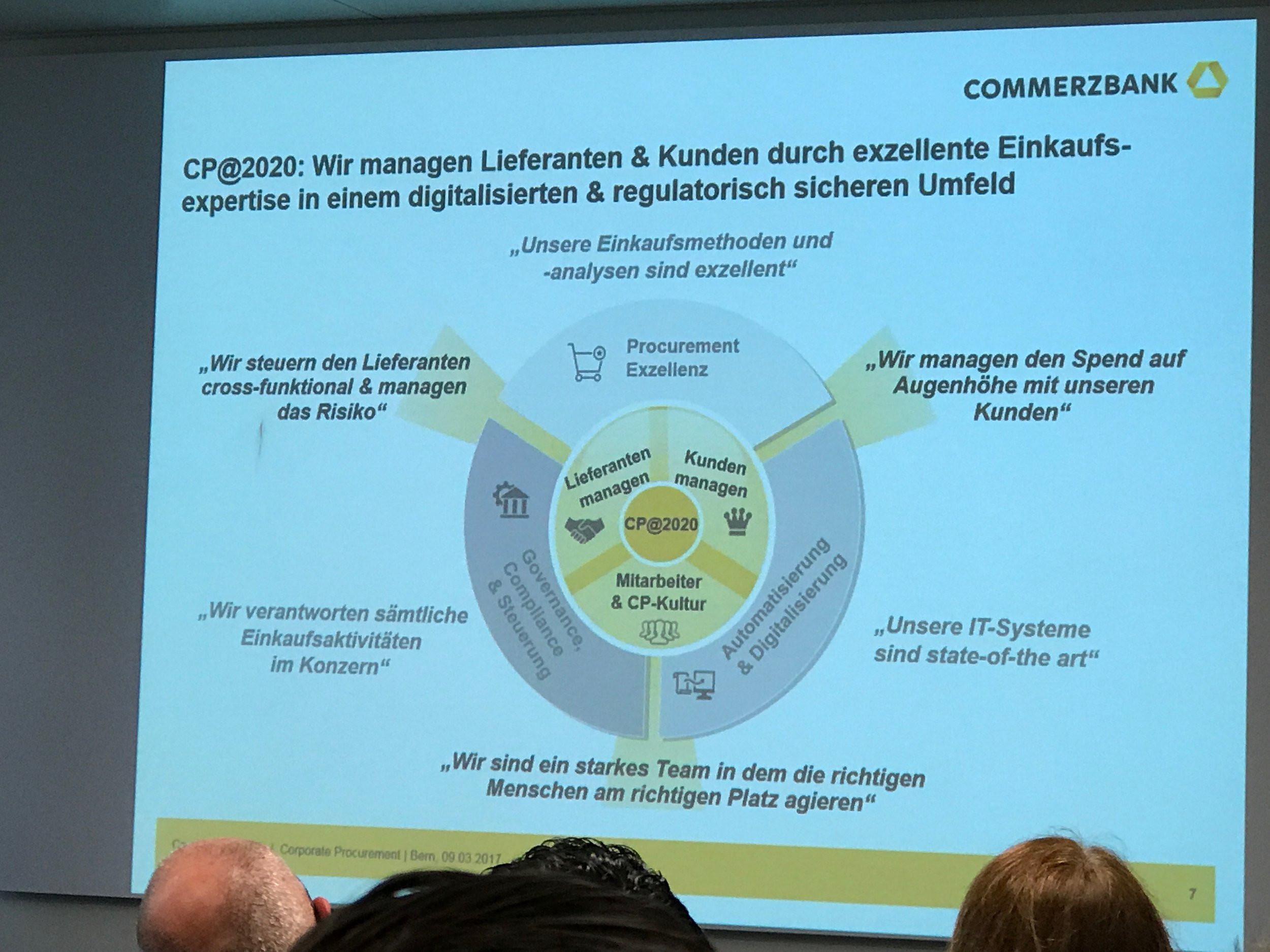

Corporate Procurement@Commerzbank AG: A competent business enabler

-- Petra Eberlein-Kemper, Head of Corporate Procurement Commerzbank AG

- Results: The Commerzbank has a big order volume in business services and a big leverage while becoming more effective. With the strategy CSP 2018 were already good results achieved. E.g.standardization of proposals, such as Internal and external definition of fields of competences/roles and seniority levels, lead to more transparent competition and savings. Classification of suppliers, paired with empowerment/selfservice per area lead to faster decisions and improved time-to-market.

Banks, as Mrs. Eberlein-Kemper told, are just before difficult, unpredicted times triggered by disruption trough digitalization (e.g. blockchain). That’s why the Commerzbank is investing already in a lot of start-ups. Procurement of start-ups, or business services of start-ups, is challenging. On one hand time-to-market is the major KPI, otherwise window-of-oppertiunity gets closed, on the other hand the startups are unknown and classic evaluation approaches are impossible. New disruptive approaches for procurement are needed too! - The most important lessons: Empowerment and fast decisions seems to become an unique selling proposition for the future. Looking at procurement of startups other factors than the price like similar culture, innovative capacity and time-to-market come to the fore. What does this means for future of procurement?-It has to evolve to the same values, become an innovation partner and that means agility will becomes the central asset of successful organizations.

“become agile, or die”

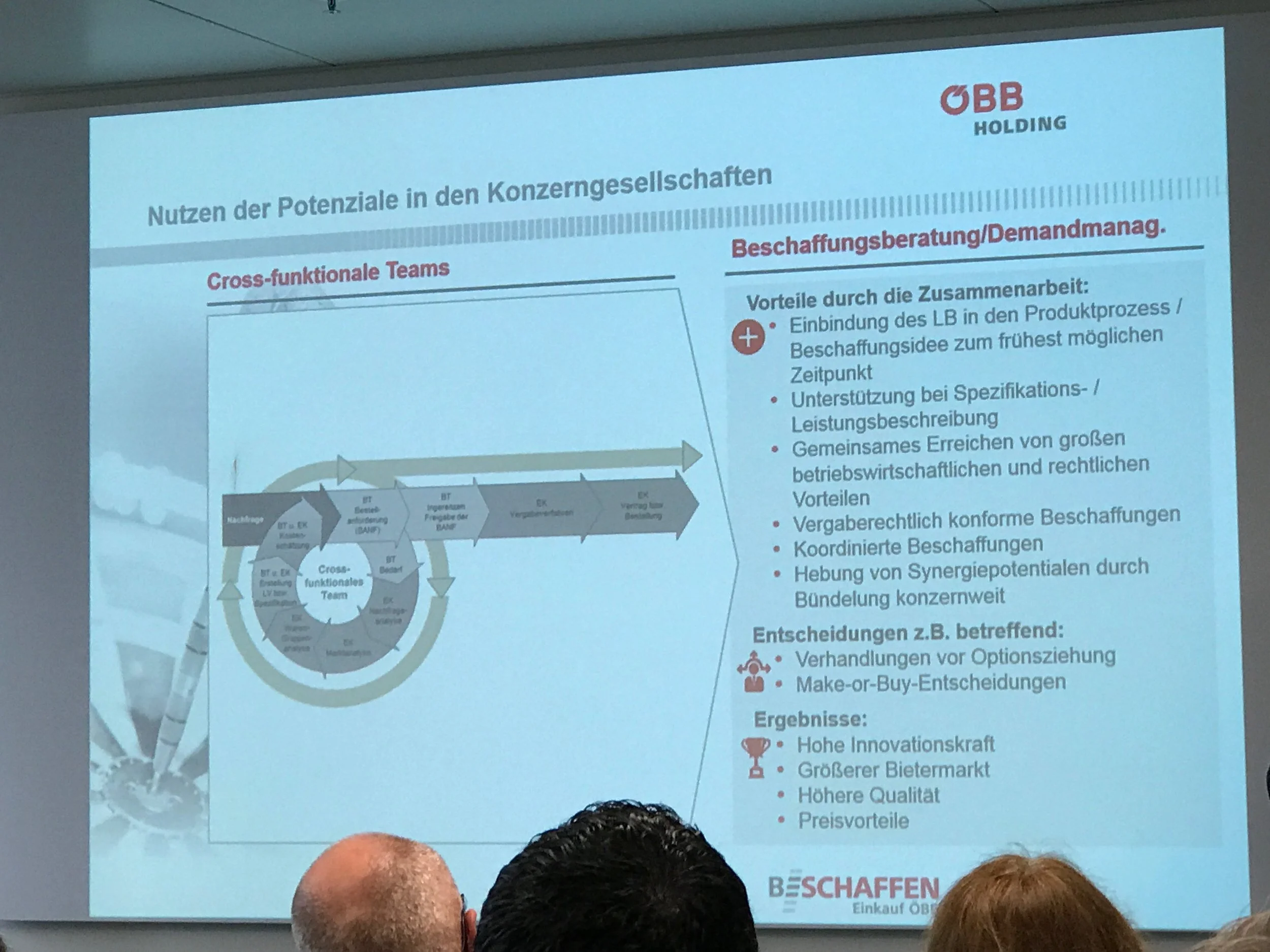

Success criterias in procurement of business services

-- Markus Wenecsek, Head of General Procurement Alliance of Austrian railways (ÖBB)

- Results: The ÖBB is facing a lot of the current challenges with missing standardization, the complexity and measurement of service quality. This is solved by empowerment and digitalization of all possiblities for procurement. E.g. simple products and services below €5k are mostly automized from request till monitoring. In area of procurement of business- or more complex services the success criterias are standardization (e.g. of roles), x-functional teams, transparency, communication, measurability and development. So has the ÖBB developed and establish an internal academy and a support organization for anyone involved in procurement. That’s why procurement is now well known in the organization and introduced in more complex procurements much earlier. That leads to a more professional, more innovative, more quality and faster contracting with more savings.

- The most important lessons: By empowerment of people that are the nearest to the customer problem and so delegation of more simpler procurement tasks majority of load could be handled via digital tools fast and compliant. Complexity in procurement of business services is approached by standardization where possible and x-functional teams. Impressive was the investment and success of development and supporting employees.

Common building blocks of all talks

procurement of business services ...

- is complex

- is hard to standardize and is lacking of specific evaluation tools or approaches

- and quality of outcome depends on customer too

- has not yet well established good practices to measure success (Customer feedback/business value over budget/costs)

- will increasingly become more complex in the future (hybrid services) and so need to increase knowhow in procurement and products. This can’t be handled by procurement alone in the future. This will become more of a team effort

- Investment in training, support and collaboration is valuable for the whole organization.

- needs more of collaboration, feedback andcontinuous improvement of customer and partner

- Modern company culture (Empowerment) and fast decisions (time-to-market) will become an asset.

- Partnering, or value-based procurement seems to be the most promising approach for procurement of business services

Special Thanks to Erik Hoffmann and the Team of procure.ch, it was a pleasure meeting you in person!

Sources (Content & Images):

- Presentation and Performance Excellence Study 2016 of UNISG

- Presentations of the top performers ÖBB, MunichRE, Deutsche Post DHL, Schindler Management AG, Commerzbank AG

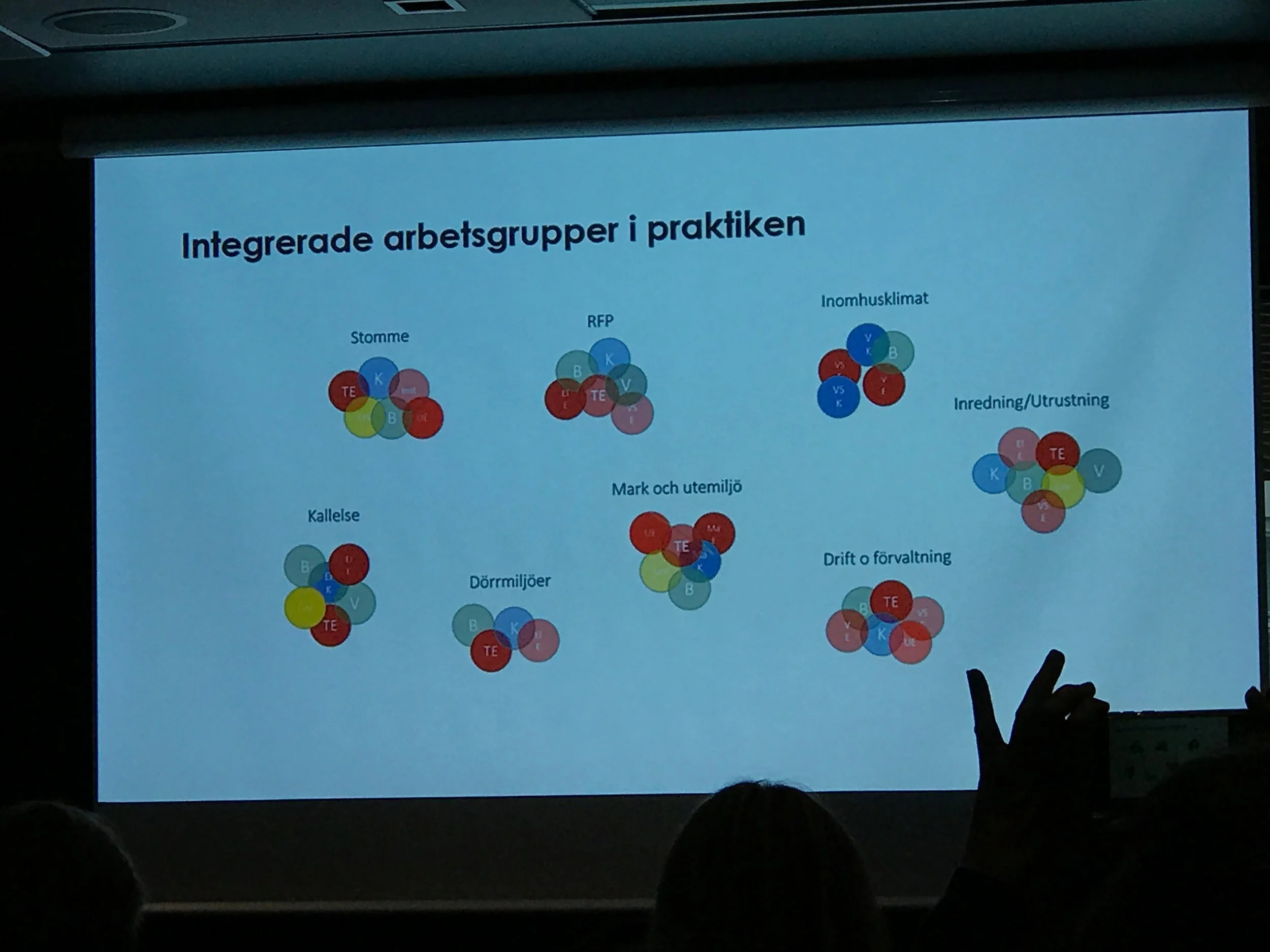

How Karlstad Hospital accomplished Objectives through Partnering and Agile Contracts

Karlstad Hospital has procured new construction and extension in order to conduct effective care with a budget of about €105 million. The new construction was built on time, on budget and was ready for business on Day 1. The hospital has also saved Värmland County Council €300 million. The secret?-Agile contracts, partnering and fully focusing on the target. So what created the conditions for success? We interviewed Lars Nilsson, the Head of Procurement at Karlstad Hospital.

Karlstad Hospital has procured new construction and extension in order to conduct effective care with a budget of about €105 million. The new construction was built on time, on budget and was ready for business on Day 1. The hospital has also saved Värmland County Council €300 million. The secret?-Agile contracts, partnering and fully focusing on the target. So what created the conditions for success? We interviewed Lars Nilsson, the Head of Procurement at Karlstad Hospital.

Big thanks to agilakontrakt.se for sharing and translating this awesome case from Swedish into English!

Interview with Lars Nilsson, Property Manager @ Värmland County Council held and translated by members of the conference board, published on agilakontrakt.se

Lars Nilsson, Head of Procurement at Karlstad Hospital.

Tell us a little about Karlstad Hospital

The Central Hospital in Karlstad suffered from severe indoor environment problems and huge overcrowding since the early 90's. To address these problems, we needed both renovation and new construction. For reasons of capacity, healthcare operations could not simply be evacuated from the existing buildings. We needed to find new ways to ensure that health care operations could be continued safely in parallel with the construction.

The first rebuilding/refurbishment phase comprised about 25,000 sq. meters. We have used the same approach for the construction of facilities for medical services and internal medical care of about 24 000 sq. meters, new psychiatry premises of approximately 13,000 sq. meters, a new surgery building of 26,000 sq. meters and we continued rebuilding and refurbishing about 30,000 sq. meters of care premises in Karlstad.

The construction projects entailed huge economic investments, that is why it required a careful quality assessment of the economic circumstances in order to make all involved parties feel reassured.

What made you choose the “partnering” model for procurement?

It seemed absurd to us that the problems we were facing could be unique to us. Surely we were not alone. We have seen precedents in England where hospitals have started to work in a new and different way in new construction projects. The clients agreed with the contractors upfront about the profit they would need to make to take on a building project. The care business, the contractors and planners then work closely together to seize all opportunities to create maximum patient benefit within the financial constraints. With our Swedish law as a starting point, we tried to create conditions for something similar in Karlstad. Sure, some think it was a gamble, but we were convinced that we had no alternative and we did not really know what "partnering" was all about.

You did not choose the traditional fixed-price contract, why not?

For the rebuilding project, it was not possible to provide the clear conditions needed for a fixed-price contract. Given the poor condition of the buildings, we were not sure of the best order in which the projects should be implemented. Once we were able to determine which sub-projects were the most acute, we wanted to take advantage of all opportunities to create the best conditions for health care operations. So we allowed those who were to physically do the work of designing this as closely as possible, to have a dialogue with the people who would operate in the premises. We wanted every project participant's focus to be 100% directed towards creating the most optimal care in our new hospital, rather than seeking to maximize one’s own economic gains. All of this would take place in an environment where everyone felt safe. We met both our financial objectives and our delivery dates.

Looking back, what was the outcome?

Operationally,

If we look at the operational outcome, there are three points I want to emphasize:

- We succeeded in creating two new and innovative solutions that made the premises well suited to the care that would be conducted and to have a low maintenance cost. For example, by using smart materials, we have minimized the maintenance disruptions to the care business.

- We have also found good solutions to energy issues that have reduced our need to purchase energy. As a reference, in 1999, Värmland County Council purchased the most energy of all county councils in Sweden per square meter of floor space. In 2011, Värmland County Council bought the least. This saved Värmland County Council some €250 to €300 million over a 10-year period when compared with other similar local stocks for care (similar hospitals). We have a registered patent in heating as a result of the project. This change is not merely the result of having made good decisions in construction projects. Rather, it is the culmination of the efforts of many people in focusing on efficient energy use. Värmland County Council now has low local costs compared to other premises in which care is conducted to a similar standard.

Time and Budget

We have kept all our schedules and we have also saved quite a few million Euros compared to initial budgets. The Operation building was completed four months before actual scheduled use (built between 2011 and 2016). The execution phase only took 40-70% of the normal time for comparable projects.

Quality

We chose our materials wisely to minimize the use of chemicals in sensitive areas such as the Neonatal Department (for premature babies). The Operation building which has just been put into use was awarded the “Lead Healthcare Gold” building classification.

We would not have been able to achieve this had we taken other approaches such as using contractor forms. The difference was due to the fact that we always chose materials that have characteristics best suited to the situation, rather than purely based on economic incentives for the supplier.

Design and Construction

We have also innovated in the development of new construction techniques over time. A small but concrete example is how we solved the logistics of fastening pipes and conduits for water, gas, electricity and heat when the new rooms were being built. Since pipes are usually mounted a bracket at a time, it can be harder and harder for the contractor down the line to access the wall or ceiling to attach the next pipe or conduit. In our case, we innovated a new way of work which allowed the first contractor to create mounts that would work for all types of pipes and conduits, which makes it both faster and smoother for subsequent construction workers to do their jobs.

An important factor for this was that we were able to make decisions on the spot, as soon as we discovered that conditions have changed. If we find on inspection that the existing walls were in worse condition than we believed, the staff in place could make decisions on the spot about the changes that the project needed to make. No need to wait for decisions to be made in steering groups, we could move to action on the spot.

The time between completing half of the quality assured space is usually extremely short, like 1-2 days. In a typical project, the time between the completed building and inspection can take anywhere from 6 to 12 months.

As you can see, we innovated in several areas, from the way health care business is conducted to energy and building technology.

What are the key factors behind the success?

I want to highlight three factors:

1st

The first important factor is that we have been able to choose appropriate skills, partners and materials most suited to solve the business problems at hand, without anyone having a personal interest in the choices made. It has been made possible because suppliers know what they will earn on the project upfront and that both parties have found it reasonable. As for financial compensation, all participants in the project can put 100% of their energy on solving business problems instead of pushing for their own more expensive solutions in order to maximize gain.

2nd

The second factor is our power control. We set up clear business goals we want to achieve early on and we continuously monitor how we were reaching our goals during the project. This allows us to adapt the solution to business problems instead of the other way around. It may sound obvious, but in reality, it’s very difficult to achieve. For the goals to be effective, they had to be formulated to be easily comprehensible, actively followed up and acted upon.

3rd

The third factor is the use of prototyping and the fact that the buildings were built step by step. We did not build all of the buildings all at once, but one at a time. It enabled us to benefit from what we’ve learned from building one building to the next.

We used prototyping for many types of rooms, from the operating room to the restrooms. Step 1: we model the building throughout and the rooms in 3D. Step 2: we create prototypes of the rooms in full scale, equipped with the intended equipment. This allows doctors and nurses to try out real life scenarios and make adjustments to the room in order to find the optimal setup for smooth operation. In the final step, the real room is built.

But don’t you know how to build a toilet?

To build a toilet is quite simple. But how do you adapt that to the space outside or to a number of different care situations? Usually, such a room is designed by an architect with limited experience of care situations. This means that they may not always be optimal when used in real life.

Let's talk a little about procurement. What did you procure in terms of performance, skills and abilities?

In practice, we procured resources and knowledge in several areas. In parallel, we made sure to build up the client's skills so that they could have meaningful dialogues with contractors and manage the project.

Can you describe the criteria for selecting vendors? How much weight was attributed to economics and how much to other factors?

The financial part is about 20%. The other 80% is made up of knowledge, quality and competence.

What did the economic model look like?

It’s a twofold economic model. The first was to eliminate all economic and short-term incentives. We simply removed the issue of economics from the table. The second was to ensure that the vendors (construction companies) remained within the framework laid out.

Compensation is broken down into fixed and variable. For the moving part, we pay the net cost for all expended time and materials, without mark up. Examples would be all of the participant's salary or purchase cost of materials net of contractor discounts. To ensure transparency, it is a requirement that all parties work with open books.

The fixed part is a supplement to the moving part. It covers central administrative overhead costs and the profit margins of contractors. Contractors would bid on the profit margin percentage. To avoid frivolous bids, we specified a percentage range based on the industry average. The result is that the contractor knows what they will earn on the project upfront and that it is reasonable.

How did you estimate the financial framework for the project?

The project is divided into phases. The contract covers the supplier for both Phase1 and Phase2. Legally however, the order letter (range) has to be on hand for Phase2 to be launched.

Phase 1 - Effect

Here the business objectives and the solution is designed in 3D. It gives us a rough estimate of the time and the material scope.

We validate the solutions we come up with to see if the client's goals are met or not. For us to move on to the next phase, we need to be confident that we can meet the business requirements as well within our time and financial constraints.

Options and Obligations

Phase 1 provides an opportunity for the client to implement Phase2, but not an obligation.

To move to the next phase, an Order Letter is created.

Order Letter

The Order Letter indicates the final range for Phase2.

Here we get a more detailed picture of the total cost and project planning.

The purchaser has the option to terminate the project if the deviation proves to be too great.

The supplier does not however have the option to pull out.

Phase 2 - Implementation

Purchaser’s goals are broken down into project goals, and then further into targets for each construction partner participant in the project.

The solution is implemented during this phase.

The economy is monitored continuously.

The project objectives are monitored as part of the project plan 2 times per year.

There is also a built-in risk sharing model for all participants. If the variable costs have a variance of more than 5% (which in turn impacts central administration costs and profit), this variance is then deducted from the profit margin.

Are there other clauses of importance in the tender documentation?